Slurry pumps play a crucial role in industrial applications, handling abrasive and high-density materials in sectors such as mining, power generation, and chemical processing. These specialized pumps are engineered to move slurry—a mixture of solid particles and liquid—efficiently and reliably.

Their ability to withstand extreme conditions makes them indispensable across multiple industries where the transportation of heavy and viscous substances is required. Without these pumps, many industries would struggle with inefficient material movement, leading to operational bottlenecks.

The right slurry pump selection can enhance productivity, reduce maintenance costs, and extend equipment lifespan. As industries continue to evolve, advancements in slurry pump technology further improve efficiency and reliability in handling demanding applications.

Contents

Mining and Mineral Processing

Mining operations depend on slurry pumps for transporting extracted materials through various stages of processing. From ore extraction to tailings management, these pumps ensure continuous movement of slurries containing metals, minerals, and waste materials. The abrasive nature of mining slurry requires pumps designed with durable materials that resist wear and tear.

High-pressure systems are often necessary to move slurries over long distances, ensuring uninterrupted production flow. Advanced sealing mechanisms and specialized impellers help reduce downtime by preventing clogging and premature wear. Without them, mineral processing would be inefficient, leading to delays and increased operational costs.

Power Generation and Ash Handling

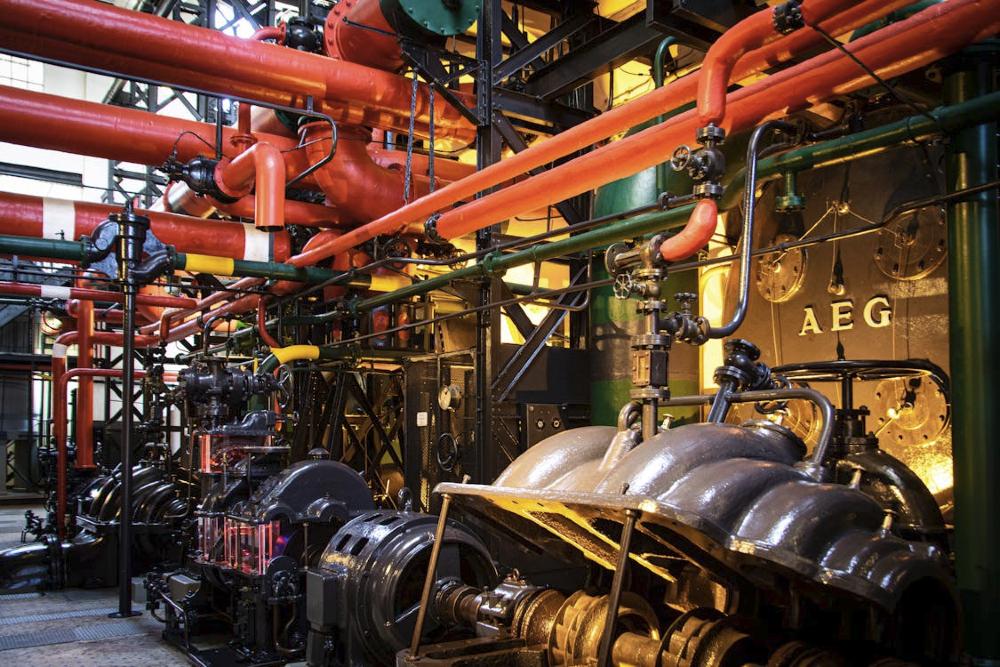

Thermal power plants generate large amounts of ash as a byproduct of burning coal. To manage this waste effectively, slurry pumps transport the ash in a liquid form to disposal sites or recycling facilities. The high-temperature conditions in power plants demand pumps that can handle both heat and abrasive particles without compromising performance.

Robust materials such as high-chrome alloys and ceramic liners are commonly used to enhance pump durability. Efficient ash handling is critical for compliance with environmental regulations and ensuring smooth plant operations. Without reliable slurry pumps, power plants would face difficulties in maintaining operational efficiency and environmental compliance.

Chemical Processing and Waste Treatment

Industries dealing with chemicals and hazardous substances rely on slurry pumps to transfer corrosive and abrasive materials safely. In chemical processing plants, these pumps move acids, solvents, and other industrial slurries through production systems.

Waste treatment facilities also use them to handle sludge and contaminated liquids, ensuring proper disposal and minimizing environmental impact. The selection of pump materials, such as stainless steel or specialized coatings, is crucial for resistance against aggressive chemicals.

Automated monitoring systems are often integrated to detect potential leaks and maintain safe operation. Selecting the right pump type is essential to maintain operational safety and efficiency in these demanding environments.

Construction and Infrastructure Development

Construction projects often require slurry pumps for dewatering and transporting cement mixtures. Whether used in tunneling, foundation work, or dredging operations, these pumps provide a reliable solution for handling thick and sediment-laden fluids.

In large-scale infrastructure projects, continuous slurry movement is necessary to maintain workflow and prevent delays. Pumps used in construction must withstand high-impact environments and fluctuating operating conditions.

Regular maintenance and proper selection of pump components ensure longevity and efficiency in heavy-duty applications. Their ability to manage high-viscosity materials makes them indispensable in construction applications that involve large volumes of slurry.

Advancements in Pump Technology

Recent developments in slurry pump technology have focused on increasing durability and efficiency. Innovations such as wear-resistant coatings, improved sealing mechanisms, and enhanced hydraulic designs contribute to longer pump lifespans and reduced maintenance needs.

In many industries, upgrading to newer pump models improves overall productivity while minimizing equipment failures. Engineers continue to refine pump designs to meet the evolving demands of industrial applications.

Industrial facilities often integrate slurry recirculation pumps to improve process efficiency and material handling. These pumps help maintain consistent slurry flow by recirculating material through processing systems, preventing sediment buildup and ensuring uniform distribution.

Their role is particularly significant in industries requiring continuous material movement, where inconsistent flow can lead to production bottlenecks. Properly configured recirculation systems optimize performance and reduce wear on primary pumping equipment, extending operational longevity.

Slurry Pumps in Dredging and Marine Applications

Dredging operations depend on slurry pumps to transport sediment, sand, and other materials from water bodies. Harbors, rivers, and coastal areas require periodic dredging to maintain navigable waterways and prevent sediment buildup.

These pumps facilitate the removal of underwater deposits, ensuring safe and efficient shipping routes. In marine applications, slurry pumps must be resistant to saltwater corrosion and biological fouling. Proper pump selection can significantly reduce maintenance costs and operational downtime.

The harsh marine environment necessitates corrosion-resistant materials, making pump durability a key consideration in such applications.

Slurry pumps are indispensable across various industries, ensuring the efficient and reliable transportation of abrasive and high-density materials. Their ability to handle extreme conditions makes them essential for operations in mining, power generation, chemical processing, construction, dredging, and food production.

As industries continue to grow, advancements in pump technology further enhance durability, efficiency, and cost-effectiveness. Investing in the right slurry pump system is crucial for maintaining smooth operations, reducing downtime, and improving overall productivity.